Optimized & Industry-ready Solutions

For All Your Needs

At Sylvester Sheet Metal, we love designing, improving, and developing products. We stand by our quality and ensure that our customers needs are met every time. All of our departments are run by skilled technicians who understand the importance of quality service and affordability. Our departments below break down each and every area of our 31,000 square foot manufacturing facility. We have the experience and technology to meet your needs.

Our Departments

SUPERIOR SHEET METAL FABRICATION SERVICES

Sales Department

Sylvester Sheet Metal's Sales Department prides itself in providing customers and potential customers with service in a timely manner. We welcome any questions that may help our customers within design and production stages.

Quotes are always provided quickly, and on time. Our estimates are created using the latest version of Visual Manufacturing Software. This software provides us with the ability to review all previous work and use the knowledge of “true labor time” for future quotes. Along with this ability, we have up-to-date pricing on our extensive material and hardware inventory. This database of labor time and up-to-date costs provides us with the ability to provide accurate and timely quotes.

The use of this software also allows for constant monitoring of work flow from order entry to shipping. It gives us the ability to immediately identify part location and fabrication progress, allowing us to be proactive in customer communication regarding order status.

Forming Department

Our Forming Department includes the following equipment:

- Amada Robotic 10’ ATC Press Brake HG1003

- 2-Amada Press Brakes RG100 equipped with NC9EX Back Gauges

- 2-Amada HRB Robotic 10FT

- Amada Press brake RG35 equipped with a NC9EX Back Gauge

Sylvester Sheet Metal's forming department has multiple Amada press brakes with up to one-hundred-ton capacity. We recently invested in an Amada Robotic ATC HG1003 Press brake. This state-of-the-art press brake enables us to program and download forming sequences from our engineering department before the job hits the floor. The robotic tool changer quickly sets up tooling, reducing setup time drastically. Our other press brakes are equipped with NC9EX back gages to provide the greatest accuracy available for forming precision sheet metal parts. We have forming capability up to ten feet long.

Welding/Grinding Department

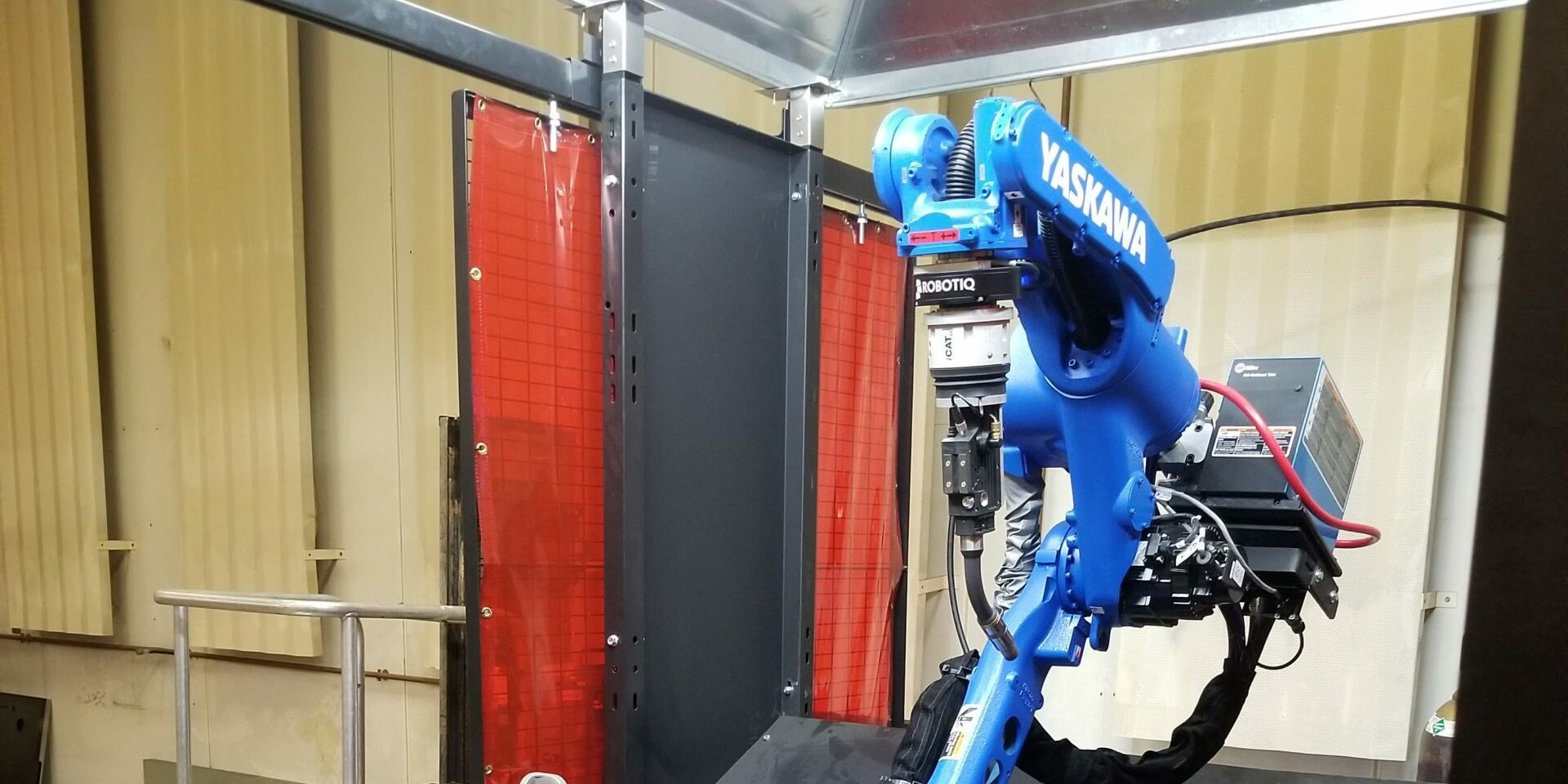

Our Welding/Grinding Department includes the following equipment:

- 2-Yaskawa Robotic MIG Welder [All Steel and Al.]

- Multiple Thermal Arc 300 GTSW Welders

- Multiple Miller Syncrowave 351 Welders

- Multiple Millermatic (250-350) MIG Welders

- Empire Bead Blasting Booth

- SURFOX 305 Surface Electro/Chemical Weld Cleaner

- 45" Costa Dry Sander with Wet Vac

Our large Welding Department offers a variety of welding methods to process a variety of metals. Whether your requirement involves TIG welding, MIG welding, Spot welding, or Aluminum Steel Stainless, our experienced welders use a good variety of equipment and can handle your needs. We also have Robotic welding capabilities. This process gives us the ability to program and fixture certain parts, so that we can decrease production costs by increasing throughput speeds. This process does not affect reliability or quality of the end product.

Our Grinding and Polish department complements our Welding Department by finishing welded seams to most any specification required. Our grinding/polishing technicians work with most common material types and finishes from Orbital sanded aluminum to #4 polished Stainless.

Quality Control Department

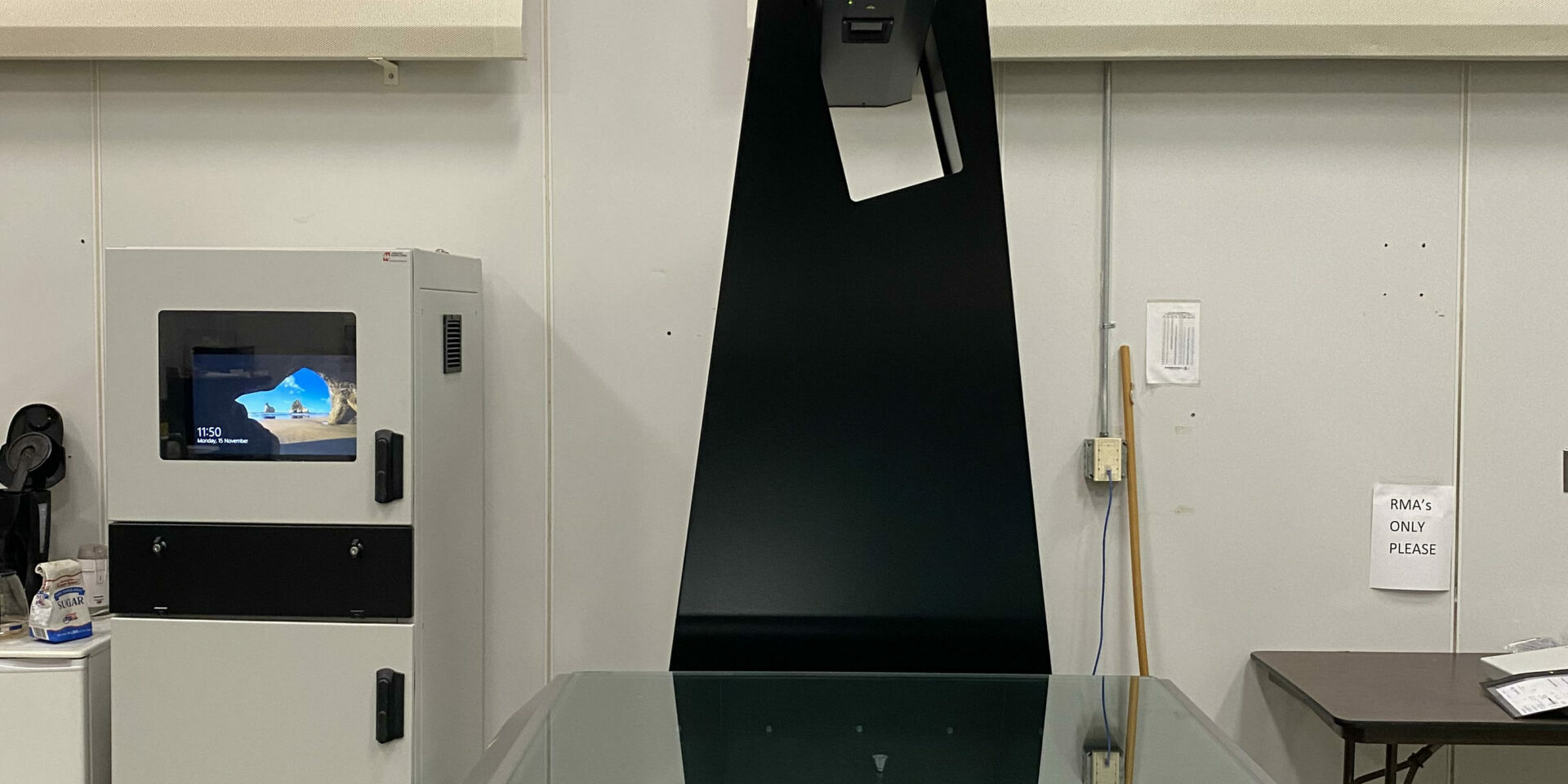

Our Quality Control Department includes the following equipment:

- Brown and Sharp Reflex 454 Coordinate Measuring Machine

- Measuring tools include Controlled Verniers and micrometers, pin and thread gauges

Our Quality Control Department ensures that our fabricated product adheres to the defined set of quality criteria set forth by our customers. This quality assurance begins with the use of measuring equipment throughout the shop that is calibrated by an outside service on a regular schedule.

All parts are inspected prior to shipping. First article inspections per our customers’ requirements. Our quality manual is available upon request.

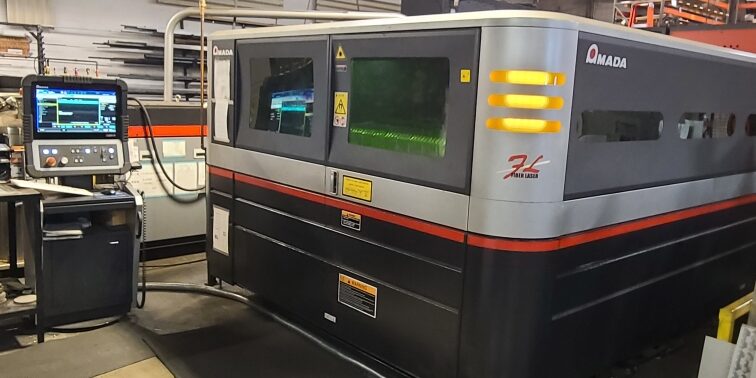

Laser/Punching Department

Our Laser/Punching Department includes the following equipment:

- Amada FOL3015AJ 4000-watt Fiber optic laser with auto load and unload capabilities.

- Amada Pulsar LC-2415 2000-watt laser with auto load and unload capabilities.

- Amada EMK 3612 M2 Punch, Auto Loader and Unload [Full Lights Out]

Our 4000-watt Fiber laser enables us to cut stainless and steel from .010” thick to .500” thick and aluminum up to .500” thick. This laser is also able to laser cut copper and bronze. The ability to fast cut various metals without compromising accuracy gives us a competitive edge in the market place. The auto loading and unloading lets us run this machine lights out with 24/7 capacity. Even though our 2000-watt Pulsar laser is less powerful, it provides us the ability to run multiple jobs at a time, again with auto loading and unloading capabilities for 24/7 capacity.

Our fifty-two station turret punch presses are tooled using and extensive inventory of punches and dies. These Hydraulic punch presses also offer forming and coining capabilities. We also have auto-loading and unloading capabilities available as well.

Engineering Department

Sylvester Sheet Metal's Engineering Department uses the information provided to us by our customers to layout cutting and forming data for our shop. We have engineers and programmers that are well experienced in the manufacturing environment and are able to provide important information that is critical to the success of any project. We utilize Solid Works and Sheet Works and are able to use provided models, dxf files, standard drawings, and even sketches. Using the latest software, we are able to maximize the use of materials inevitably, keeping costs down.

Machining Department

Our Machining Department includes the following equipment:

- OKUMA L300-M Multi Access Turning Center

- 2-OKUMA CADET-MATE Machine Centers

- Saw - Dragon Bend Tech Plasma Cutter

Our Machining Department is primarily used to support our sheet metal fabrications and assemblies. Although this department is small, we have the key machines that give us the opportunity to provide a well-rounded machining capacity. Our machine and turning centers interface with CAD/CAM, Solid Works, and CAMWorks software generated programs from our Engineering Department.

Powder Coating/Silk Screening Department

Our in-house Powder Coating Department gives us the ability to provide a cost-effective durable finish on a variety of base metals. We can also provide in-house Silk Screening as required. Along with Powder Coating and Silk-Screening, we work with several local Finishing partners to provide a range of finishing capabilities such as Liquid Paint, Anodization, Zinc, and Chromated finishes.

Assembly Department

Our Assembly Department is able to provide mechanical assembly capabilities that meet any of our customers’ requirements. Our manufacturing software will schedule and allocate all hardware and materials required for assemblies to keep orders on time and on schedule.